Tormach Inc./YouTube

Tormach Inc./YouTube

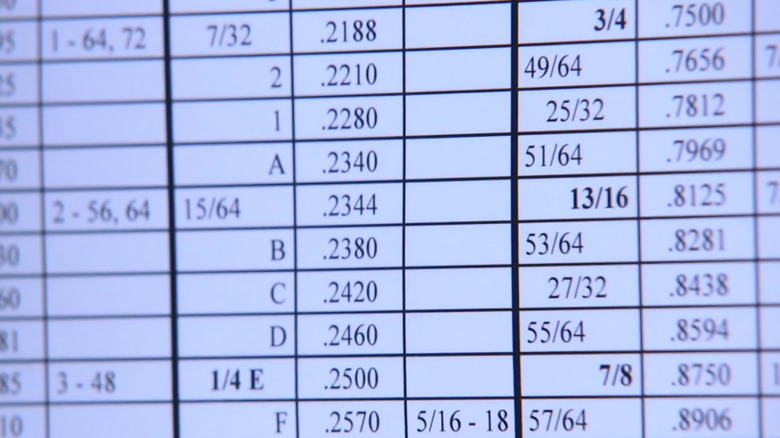

See a letter "A" on your drill bit? You're holding the first and smallest size in the letter-gauge drilling system. Perhaps unsurprisingly, this standardized series runs alphabetically from A to Z. On a standardized drill size chart, an A-size bit should measure 0.234 inches, or 5.94 millimeters. (That's ever so slightly larger than the largest numbered bit in the all-important wire-gauge system.)

As sizes progress from A to Z, the diameters increase, eventually reaching 0.413 inches (10.49 millimeters) at letter Z. These lettered drill bits can bridge the size gap between wire-gauge bits and fractional sizes. Wire-gauge bits start at an extremely small size of #80 (0.0135 inches) and increase to size #1 (0.228 inches). Once wire sizes are exhausted, letter sizes begin.

Fractional bits, by comparison, follow the U.S. imperial system. They increase in fixed increments of 1/64 inch, and they typically cover sizes between 1/64 and 1 inch. Metric bits follow ISO standards and usually rise in 0.1-millimeter increments. (This is also in line with global metric thread and fastener systems.) They're all part of a broader set of drill measurement systems that have evolved throughout industrial history.

Why the 'A' matters

Tormach Inc./YouTube

Tormach Inc./YouTube

The letter-gauge drilling system gives people access to sizes not available in other fractional or metric sets. This comes in handy, especially when tight tolerance makes all the difference. Whether you're a CNC machinist, a manufacturer, or a hobbyist, it's never a bad thing to have a more precise range of options to work with.

Making the mistake of using the wrong drill bit might not make the biggest difference in the world for a weekend DIY project where "close enough" can still get the job done. But for professionals, these sizing systems are definitely not interchangeable. Even tiny differences matter when it comes to threading, hole tolerances, or fastener fit. For example, a #7 drill bit measures 0.201 inches, while a 13/64-inch bit measures 0.2031 inches. That difference can determine whether a tapped thread fits securely or ends up stripped.

Letter bits help fill in some of the gaps of other systems by offering you some additional increments between standard sizes. This is why A-through-Z bits are still used today and remain an essential part of many machinists' toolkits. (Just don't let the directions trip you up: the numbers and letters move in opposite directions. Numbered bits get smaller as the numbers increase, while letter bits get larger as the alphabet advances.)